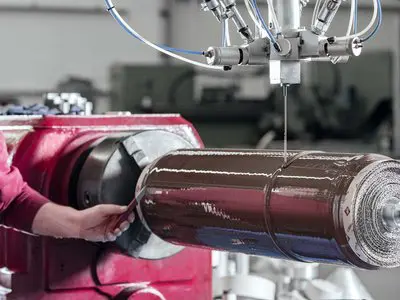

We offer a wide range coatings and strive to meet the highest demands for industrial applications. We dont compromises on quality of our roller’s surface and fully comply with individual wishes of our customers.

The following are some of the typical requirements and properties:

Many years of experience of the entire Hilzinger-Clouth Group in choosing an ideal coating, guarantee our customers optimum problem solutions for their technical tasks.

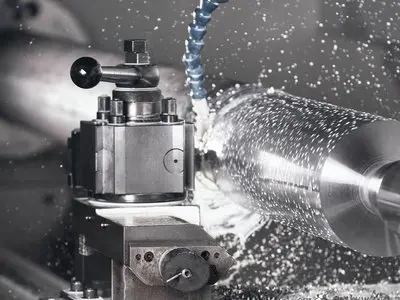

Our manufacturing dimensions for roller coatings:

Diameter: up to 2,000mm

Length: up to 12,000mm

Weight: up to 10,000kg

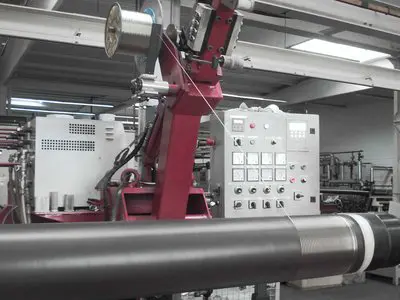

According to your individual requirements, we supply roller cores, steel rollers and other turned parts as per your drawing, in all common materials. We can polish surfaces, belt- and stone-grind. Special contours (concave or convex) and grooved designs are also part of our product portfolio.

Accompanied by a wide range of roller coatings, offered by the Hilzinger-Clouth Group, you receive everything from a single source. Your benefit are shorter delivery times and comprehensive advice.

The following properties and requirements show an excerpt of our typical product services:

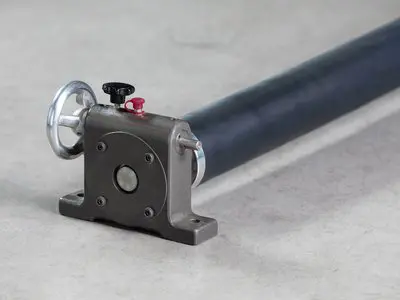

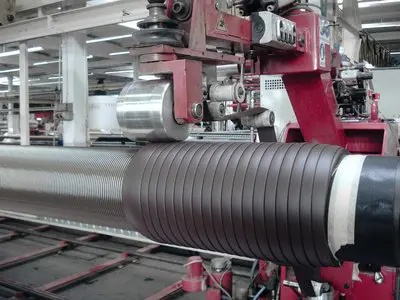

Simplified changeover in the production process, better handling due to lower weight or space-saving vertical storage are just a few of the advantages of the sleeve technology, which is used in a wide range of industries. We offer our customers rubberised sleeves from a single source. If desired, we use glass fibre reinforced plastic (GRP) or carbon fibre reinforced plastic (CFRP). Other typical properties and requirements for our sleeves are as follows:

With a wide range of different coatings for spreader rolls, Hilzinger-Clouth supplies customers in the textile, paper and film&foil industries worldwide. Depending on the requirements, rubber or polyurethane coatings are used. In addition, we offer fabric and steel wire reinforcements for speeds above 2000m/min.

In this field, with over 50 years of experience, we offer individual solutions for individual needs in all areas of applications.

Our manufacturing dimensions for temple covers:

Diameter: up to 480mm

Length: up to 11,000mm

One of the strengths of the Hilzinger-Clouth Group is, finding flexible solutions for different industries and applications. In doing so, we also look beyond the end of our nose 😉 and develop special products from our deep range of elastomers together with our customers.

At Hilzinger-Clouth we combine our wide product range for rollers with a comprehensive service offer for your specific application. Our all-round package ranges from individual advice and maintenance of your rollers to the required logistics.

Cleaning of roll covers

From time to time, it is necessary to clean the surface of elastomer-coated rolls of contaminants and residues such as dyes, resins, oils, etc.

The cleaning can be done independently of the elastomer mixture by warm soapy water.

If this cleaning is not sufficient, please take a look on our cleaning recommendations, which shows usable solvents with consideration of the elastomer mixture.

Storage of elastomer-coated rollers

Elastomeric roller coatings can undergo changes in atmospheric oxygen, ozone, moisture, too cold or too warm ambient temperature of storage or solvents.

Correct treatment extends the life of covered rolls.

Guidelines for the treatment of rubber products are contained in DIN 7716.

Moreover, please take a look on our storage recommendation for elastomer-coated rollers.