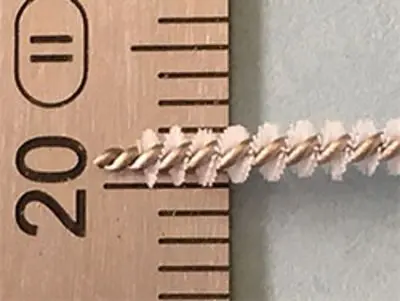

Strip brushe, ring brushes and spiral brushes are made with the same base-technology.

A metal strip is filled with bristles without any gaps and then closed in the middle by inserting a fixation wire.

The advantages of this brush system: great flexibility in terms of fill material, fill density and geometries as well as unsurpassed advantageous mechanical properties.

Strip brushes also represent the best of all available brush systems for thermally highly demanding operating conditions with large temperature tolerance fields. They easily cope with extremely low or high temperatures as well as temperature fluctuations and do not become brittle.

In the list of our standard strip brushes you will find information about dimensions and materials used.

HT strip brushes are used for sealing, cleaning and deburring of round material. Fields of applications are the automotive industry, the construction industry, mechanical engineering as well as the cleaning industry.

Spiral brushes or roller brushes are mainly used for cleaning, application, transporting and deburring.

As customer-specific products, HT strip brushes can be bent, set in profiles and provided with grooves for fastenings. Examples are our corner brushes, brush rings and strip brushes for doormat systems.

Technical brushes for industrial use.

To produce punched brushes, the fill material is stuffed into a body provided with drilled holes and fixed in the base by means of a wire loop punched into the brush body.

There are virtually no limits to the variety of fill material, core material and core geometry. The most economical materials are selected in each case according to customer-specific technical requirements.

Our proprietary ORP process (Online Recycling Process) for the production of thick-walled plastic parts by injection molding allows us to economically manufacture brush cores in medium quantities (500 to 5,000 units per year). This is made possible through the cost-effective production of the required tools.

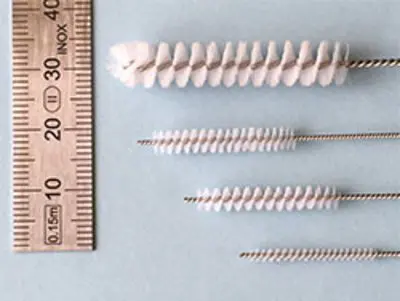

HT pipe brushes are used for small bores. Many different types are available. We are happy to convert your specific requirements into the design of a highly effective brush.

Almost infinite possibilities…

Our production facilities are capable of manufacturing almost any pipe brush you require.

Diameters are starting from tiny 0.9mm and go up to 200mm.

Total lengths of a few centimeters up to several meters can be precisely realized.

The following materials are available:

Simple end

The standard version of our pipe brush head is an open end.

Flat eyelet

An alternative to the standard version is a flat eyelet. With this version, the fill material can be inserted until the brush tip. The bent wire at the brush tip has no sharp edges and helps to protect delicate surfaces from getting scratched.

Brush head with fan

Another option is a fan shaped tip. The bristles are forming the head of the brush. This design prevents contact of the brush’s twisted wire centre with the workpiece surface.

Holders

Big or small eyelets, straight end, shaft, …

You name it, we do it.