The practice of belt grinding with contact wheels has proven that the best grinding belt can only grind as effectively as the contact wheel used permits and supports it. Only with the right contact wheel the abrasive belt can be actively used to its full potential.

Depending on the application, hard or soft coatings with or without grooves are used. The flexibility of the contact wheels can be adjusted by the hardness of the coating and sometimes also by the height of the coating.

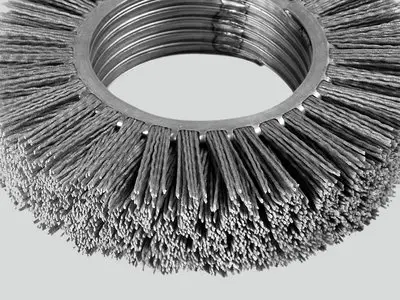

Deburring brushes are used to deburr primary or secondary burrs.

Burrs are generally undesirable in the production process, but often unavoidable. An economical method to remove these burrs and at the same time create defined edge roundings is brush deburring.

Circular brushes and disc brushes are used for deburring edges or holes on external surfaces. Our brushes are used for deburring both, stampings and milled parts.

By the special development of process-adapted deburring brushes you can optimise your process costs and throughput times. Simply tell us your deburring application – and we will work with you to develop the most suitable combination of abrasive, bristle material and geometry of the deburring brush.

Tube brushes or internal deburring brushes are used for deburring in bore holes, especially at intersections.

We manufacture the mounting side of the deburring brush according to your requirements – for example for with shank cones, for direct use in CNC machines or with special mountings, e.g. for Löser, Hesemann, Wolters, Weber, Surfinsys or other machines.

Special holders for the brush can be developed by our engineering department together with you on request.

With our deburring brushes you can deburr both strong primary burrs and finer secondary burrs.

Based on the analysis of your application and specific task, we will design for you a specific and at the same time highly efficient solution for deburring with brushes.

For some workpieces, contour processing by abrasive belt is very difficult or too complicated – the perfect field of application for flap wheels (abrasive mops, sanding wheels) type B1 to type B3. While the abrasive belt on the contact wheel adapts more to the flat surface, a flap wheel easily follows even the most complex shapes and contours.

Since the tips of the flaps are used, the grinding effect and the depth of the grinding line is uniform until the grinding wheel is worn down. A new abrasive belt, on the other hand, works very sharply at the beginning, but gets clogged-up over time and loses its effect.

Abrasive strip rings and flexible abrasive belt tools:

Flexible abrasive strip rings are ideal for sanding surfaces that are very difficult to machine. Even tight radii can be ground without any problems.

For deburring or for intermediate lacquer sanding we offer sanding belt flaps (type ME) with different profiles and different slits.

Satinizing tools are made of non woven abrasives. Then non-woven fabric consists of randomly oriented nylon fibers and abrasive grit.

Satinizing tools can be used to create matt surfaces. The surface is only slightly changed. A discreet line structure covers the larger unevenness underneath. However, the base of the surface remains untouched and deep valleys are not removed. The result: During a subsequent polishing process, all remaining subliminal defects become visible in the high gloss. Therefore, these tools do not serve for pre-polishing, but rather represent a separate genre, namely tools exclusively for satinizing.

Our finishing tools are used dry or wet. Since they are heat-sensitive, cutting speed and contact pressure must remain low.

Sisal fibers are won from the Agave Sisilana plant. Sisal is a robust, natural fiber that offers unsurpassed mechanical properties in metal polishing.

Fibers up to 120 cm long are decorticated from the sisal leaves. During the decortication process, the clorophyll is scraped off the fibers with a squeegee. The fiber itself accounts for only 4 % of the leaf weight. The remaining chlorophyll is used for fertilization.

Sisal is cultivated in South America, East Africa and China. Due to the special soil conditions and climate data, the best quality of sisal fiber is found in East Africa. The East African fiber is uniformly white and shows the highest abrasion resistance. Brazilian sisal fiber, on the other hand, has a brownish coloration and still has acceptable mechanical abrasion resistance. The Chinese fiber is recognizable by its greenish color. It has the worst mechanical properties in comparison, but is the cheapest fiber available on the market.

We at Hilzinger-Thum only use first-class East African sisal fiber for our fabrics and cords. The quality of our sisal tools for pre-polishing is accordingly high.

HT sisal tools are manufactured individually for the application of our customers. We adapt density, hardness and dimensions exactly to the requirements.

Our impregnations increase tool life, strength and abrasion resistance. The different impregnations have different hardness or softness and are optimized for specific workpiece materials. Each of our impregnations can be quickly and easily identified by its color.

Tampico is another plant fiber derived from an Agave plant. It grows exclusively in the high lands of Mexico. It is shorter and stiffer then Sisal, thereofre it is used to achieve more coarse finishes. Whereas Sisal is used in matting or braid, the Tampico fiber iteself is used as bristles in brushes.

For HT polishing tools we use 100% cotton fabric for almost all applications. These fabrics are woven according to our technical specifications especially for Hilzinger-Thum. In order to meet every customer’s requirement in the best possible way, we have a wide range of fabrics: from very soft and open to very hard, heavy and extremely dense.

Our ventilated or spirally sewn polishing buffs are made of 45°-cut, highly abrasion-resistant cotton fabrics. For full leave polishing buffs, we use full and half leaves of new fabric. Stitched coloured cotton buffs are hardly used today any more. Still, we can offer them if required, mainly for manual processes. They are made of new fabric waste from the textile production such as shirting, Neubunt or inlett.

We adjust the hardness of our buffs by using different amounts of material in different geometries. In addition, the dimensions are always selected according to customer specifications. For example, we produce very soft polishing tools for customer parts made of soft materials or with a curved geometry, but also very hard polishing tools that are normally used for flat or even parts.

For high gloss polishing of sensitive and soft surfaces we offer flannel fabrics of very soft, roughened and open weave cloth.

HT Clench-Rings

Clench-rings are the cheapest method for clamping all types of polishing and sisal buffs. The clench-rings are either applied directly to a shaft adapter or used with centering discs. When used with shaft adapters, we recommend using rings with a welded driver in the claw.

HT Cardboard Core

Alternatively, a cardboard core can be integrated into the polishing buff, for particularly convenient but also more cost-intensive centering. In this case all bores can be produced.

Grinding- & polishing tools are rotating with high-speed:

Please protect your employee and and demand our safety data sheet!

Please note the safe regulations A + B for strechting of polishing rings, polishing discs and similar tools