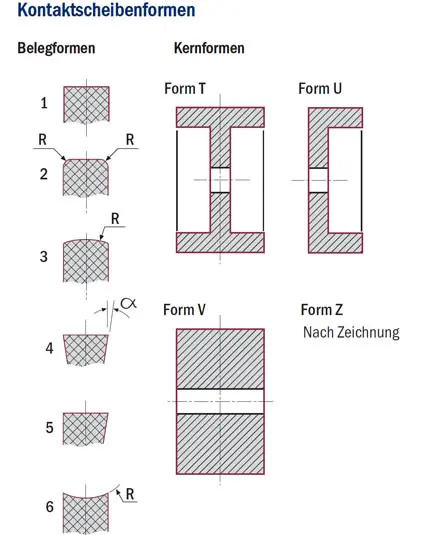

Contact wheels forms and grooving

The deeper and wider the grooving the more aggressive the effect of the abrasive grit and the higher the stock removal

Flat coated contact wheels are more ideal for finer grit size

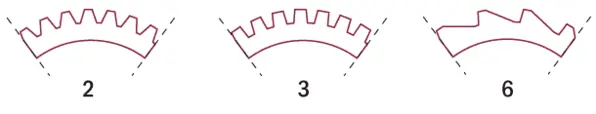

grooving Nr. 2: fine, uniform grooving for fine grinding

grooving Nr. 3: standard grooving for universal grinding (most commonly used grooving)

grooving Nr. 6: “saw-tooth” grooving for coarse grinding